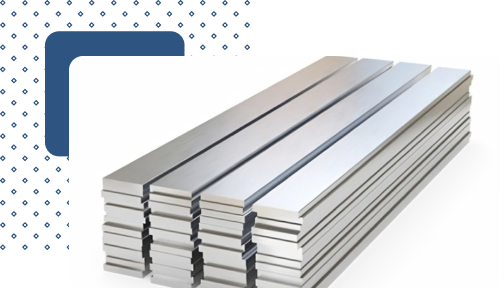

AISI 4140, EN 19 CS Bar

75 Reviews

Product Description:

Our AISI 4140 and EN 19 carbon steel bars are engineered for high-strength applications requiring excellent durability and toughness. AISI 4140 is a chromium-molybdenum alloy steel that offers exceptional hardness, wear resistance, and high tensile strength, making it ideal for automotive, aerospace, and industrial applications. EN 19, a high-strength steel grade, is known for its excellent fatigue and impact resistance, widely used in the manufacturing of high-stress components like shafts, axles, and gears. Both grades are highly versatile and suitable for heavy-duty applications requiring superior performance.

Key Specifications:

| Property | Specification |

|---|---|

| Grades | AISI 4140, EN 19 |

| Diameter | 10 mm to 500 mm (Custom sizes available) |

| Length | Custom lengths available |

| Surface Finishes | Hot rolled, Cold drawn, and customized finishes |

| Yield Strength | AISI 4140 - 415 MPa, EN 19 - 450 MPa (min) |

| Hardness | AISI 4140 - 30-35 HRC, EN 19 - 30-40 HRC |

| Tensile Strength | AISI 4140 - 850 MPa, EN 19 - 850 MPa |

| Standards | ASTM, EN |

Icon Steel offers AISI 4140 Carbon Steel (CS) Bars and EN 19 Carbon Steel (CS) Bars, two premium-grade alloyed carbon steels known for their high tensile strength, excellent toughness, and superior wear resistance. These bars are widely used in industries such as automotive, aerospace, construction, and power generation, where durability and performance under stress are critical.

Specifications and Properties

AISI 4140 is a chromium-molybdenum alloy steel that offers excellent strength, fatigue resistance, and hardenability.

Specifications:

| Property | Specification |

|---|---|

| Standard | ASTM A29, SAE J404 |

| Material Composition | ~0.38-0.43% Carbon ~0.75-1.00% Manganese ~0.80-1.10% Chromium ~0.15-0.25% Molybdenum |

| Density | 7.85 g/cm³ |

| Tensile Strength | ~950 MPa |

| Yield Strength | ~655 MPa |

| Hardness | ~197-300 HB (Brinell Hardness) |

| Applications | Heavy-duty shafts, gears, connecting rods, and automotive components |

EN 19 is a high-strength alloy steel that provides excellent impact resistance, toughness, and wear resistance, making it ideal for demanding applications.

Specifications:

| Property | Specification |

|---|---|

| Standard | BS 970, DIN 42CrMo4 |

| Material Composition | ~0.36-0.44% Carbon ~0.50-0.80% Manganese ~0.90-1.20% Chromium ~0.15-0.30% Molybdenum |

| Density | 7.85 g/cm³ |

| Tensile Strength | ~850-1000 MPa |

| Yield Strength | ~600 MPa |

| Hardness | ~220-280 HB (Brinell Hardness) |

| Applications | Crankshafts, spindles, axles, and high-performance engineering components |

Key Benefits of AISI 4140 & EN 19 Carbon Steel Bars

- High Strength & Toughness

Both AISI 4140 and EN 19 bars offer superior mechanical strength and impact resistance, making them ideal for heavy-duty applications.

- Excellent Wear & Abrasion Resistance

The presence of chromium and molybdenum enhances wear resistance, reducing component failure under stress.

- Good Machinability & Weldability

These bars provide excellent machinability and can be heat-treated to achieve customized mechanical properties.

- Versatile Industrial Applications

Both grades are widely used in industries requiring high-performance steel bars for structural and mechanical applications.

Contact Us

For more information about our AISI 4140 CS Bars and EN 19 CS Bars, or to request a custom quote, contact Icon Steel today. Our expert team is ready to deliver high-quality carbon steel solutions tailored to your industrial needs.

FAQs

What is the main difference between AISI 4140 and EN 19 carbon steel bars?

AISI 4140 is an American standard chromium-molybdenum steel known for its high tensile strength and fatigue resistance, while EN 19 is a British standard alloy steel with excellent impact resistance and wear properties.

Can AISI 4140 and EN 19 carbon steel bars be heat-treated?

Yes, both grades can be heat-treated to enhance hardness, strength, and wear resistance, depending on application requirements.

Are custom sizes and finishes available for AISI 4140 and EN 19 CS Bars?

Absolutely! Icon Steel provides customized sizes, lengths, and surface finishes to meet your specific project needs.

Subscribe Our Newsletter

Build stronger Customer Relationships with ICON STEEL

Our Pride

Our Products

UNDER ONE ROOF

Manufacturing Units

OUR STRENGTH

Quality Assurance